Why You Should Quit Using 1080 Glass

The high percentage of resin coverage can cause skew issues at higher speeds.

Since June, I’ve been writing about glass-weave skew (GWS). If you haven’t read those articles, you may want to go back and bone up on the subject. We’ll review a few points here.

A serial link’s differential-skew budget shrinks as bit rates increase. For example, a 1Gbps (500MHz) signal would have roughly 250ps of skew tolerance. That’s a wide window, and why most engineers didn’t need to worry about GWS 20+ years ago. Fast forward to 10Gbps (5GHz), and the skew tolerance will decrease proportionally to around 25ps.

When working at frequencies below 1GHz, or when using whatever materials the fabricator has in stock due to schedule constraints, don’t worry about glass style. If signaling at higher speeds and there is time to plan, read on.

As a mechanism for mitigating GWS, glass and laminate manufacturers adapted the mechanically spread glass already in use for improved laser drilling. IPC has not agreed on a definition for mechanically spreading glass. Like many aspects of the copper-clad laminate (CCL) world, a laminate’s “degree of spread” is left to the glass manufacturers, which are currently bent on keeping everything as proprietary as possible, and little has been done to quantify the degree to which glass styles differ from one another relative to the spreading of the fabric. Nevertheless, there are things we can learn from available data.

Background on 1080 glass. The history of 1080 glass is extensive. Every PCB fabricator on the planet uses it. Your fabricator, as well as the vendors selling laminate to them, have warehouse shelves stacked with sheets or panels of 1080 glass. Tied to the high-production volumes, it’s a reasonably priced alternative for the constructions it supports. Typical single-ply core thicknesses range from 2.4 to 3.5 mils. Dual-ply 1080 core constructions range from 4.0 to 7.0 mils.

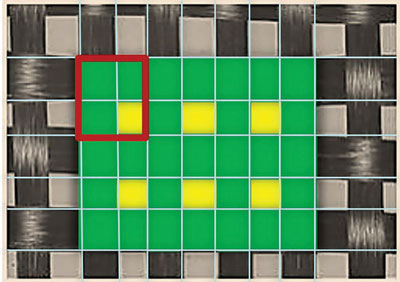

Issues with 1080 glass. What is it about 1080 glass that’s problematic for glass-weave skew? The primary concern is the fabric’s “resin windows” (my term for it) are larger than the other alternatives. FIGURE 1 shows how optical-measurement images are used to determine glass-coverage percentage (green) versus resin coverage (yellow). Ideally, for mitigating glass-weave skew, the glass coverage percentage (green) should be as high as possible. Higher glass coverage means there’s a higher probability two halves of a differential pair will “see” the same or similar Dk environment along the signal paths, all other things being equal.

FIGURE 1. Optical measurement images are used to determine glass coverage percentage (green) vs. resin coverage (yellow).

If we consider the red rectangle in Figure 1, and we know the glass pitch (TABLE 1) and the warp and fill yarn widths, it would be possible to reverse engineer the relative size of the yellow resin window we are seeking to minimize, and use this as a metric for comparing glass styles, including 1080 glass and its alternatives. Unfortunately, yarn-width data for woven fabric are not widely available.

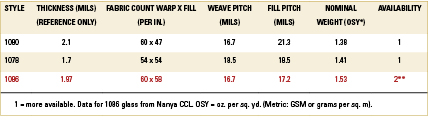

TABLE 1. IPC-4412 Parameters and Relative Availability for 1080 and 1078

One alternative to 1080 glass is 1078, which is close to a drop-in replacement, with typical single-ply core thicknesses ranging from 2.3 to 3.5 mils. Dual-ply 1078 core constructions range from 4.0 to 7.0 mils. Another alternative, 1086 glass, is thicker, with typical single-ply core thicknesses ranging from 3.0 to 3.5 mils. Dual-ply 1086 core constructions range from 5.0 to 7.0 mils.

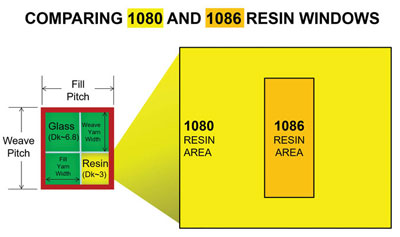

Except for 1086 glass, IPC-4412B frames the differences between these glass styles as summarized in Table 1. Using that data, along with available widths for warp and fill yarn, we can calculate the approximate size of the yellow “resin window” in Figure 1. Using available pitch and yarn-width data for normal, non-spread glass, FIGURE 2 shows the resin window that we’re seeking to minimize for 1080 glass makes up 24% of the board area (76% glass), while resin windows for 1086 glass are just 5% (95% glass), using data for non-spread glass. That’s a dramatic difference! The difference between 1078 and 1080 glass is significant as well, but not quite as dramatic. (At this writing, I only have yarn widths for Nanya glass, which is spread.) Either of these offer an advantage over 1080 glass.

FIGURE 2. The yellow resin window we’re seeking to minimize for 1080 glass makes up 24% of the board area (76% glass), far less than alternatives.

Glass symmetry. Another concern with 1080 glass is it’s asymmetrical in the warp versus fill directions. That is, it’s “asymmetrical” in the sense that yarn count in the weave and fill directions are unequal. Of the three glass styles discussed herein, 1078 is “squarest” of the three. Working from the yarn counts in Table 1, 1080 is the most asymmetrical construction, and 1086 is just a bit off. Dk and impedance are like the game of horseshoes, where getting close still helps.

The advantage here is you can align your differential signal pitch to the glass pitch, and it doesn’t matter how the board is oriented on a panel. In a later article or column, I’ll elaborate on the benefits of square weaves.